Vacuum forming

- Packing

- Advertisements

- Letters

- Logos

- Lodgments

- Blisters

Materials

- Polystyrene

- Acrylic glass

- Polycarbonate

- Solid polycarbonate

- Aluminum sheet

- Composite sheet

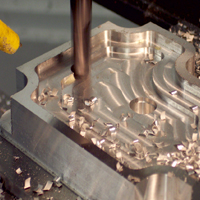

SIGN industr SRL company performs milling and engraving works by car 3d Techno-isel LC 78120 manufactured by Techno, Inc. (USA, New York). Milling and engraving machines Techno demand in production for metal, plastic, wood, MDF, etc. Techno-isel LC 78 120 completely covers niche cutting, engraving, 3D sampling, cutting and other operations with the material size 2000h3000x227 m milling and engraving machines Techno CNC, is the standard of technology, quality and reliability, which is now in Moldova.

The company also provides vacuum-forming machine of the 3d to VFE-D Super Technoimpex made by Technoimpex Trading Corp (Hungary). Vacuum forming equipment VFE-D Super Technoimpex intended for the manufacture of products such as: the details of lighting, advertising panels, spoilers, auto parts stores, refrigerator liners, blister packing, etc. size 1720h820x400 m vacuum forming machine Technoimpex, this standard of technology, quality and reliability, which is now in Moldova.

Milling (milling, milling) - cutting and handling of the material by means of a milling machine, the main part of which is the Hiller - multiblade (having a few teeth) cutting tool. In the process of milling cutter performs rotational motion, and the workpiece - directly or curved forward motion. Currently milling is widely used in engineering, design development, the manufacture of outdoor advertising.

Engraving - one of the oldest forms of art that came to us from time immemorial. To have survived a lot of bronze articles, artfully decorated with engraving. There are only two basic types of engraving: drop a thread and dotted engraving. Drop a thread - this vivid image with a selected depth and volume study of the background components ornament. The dotted pattern is engraved on the surface of the product caused by strokes and contour lines.

Vacuum forming - in essence, is a variant of drawing in which the plastic sheet, located above the matrix is heated to a certain temperature, and repeats its shape by creating a vacuum between the plastic and the matrix. This technology is widely used in outdoor advertising, automotive, food and packaging industries. Products are durable, aesthetic qualities and at the same competitive price.

Material for vacuum forming can be used a variety of: acrylic and polystyrene - clear, milky, color, ABS, PVC, PET, solid polycarbonate, etc.

Manufacture of vacuum forming products is carried out in two stages:

- Making a mold (matrix) for future products;

- Forming of the product (under the influence of vacuum).

Matrix - a special high-precision equipment, which has a relief of the final product produced by the form. Depending on the quality of the surface of the molded product, circulation order, precision performance, pricing matrix can be made from materials such as fiberglass, MDF, various resins, dyuralalyuminy. Options are combined forms (eg, stainless steel and plywood, epoxy resin and aluminum). It should be remembered only for the absence of negative angles. It is understood that all the slants, the ends of the product must have an angle of 90 ° and above.

Our company offers a fast and high quality work of any complexity and individual orders. At your service are experienced creative designers and experts who will consider all your wishes and requirements.

.png) MEDITERANA TM-55

MEDITERANA TM-55 ONDULATA PZ-30

ONDULATA PZ-30 ONDULATA PZ-18

ONDULATA PZ-18 FALTUITA FF-45

FALTUITA FF-45 FALTUITA FW-45

FALTUITA FW-45.png) SANDWICH SF-45

SANDWICH SF-45 SANDWICH SW-45

SANDWICH SW-45 SIDING SF-200

SIDING SF-200

.jpg)